Part 1: Introduction

Logistics and Supply Chain can be assumed as “STARS” which completes the

“CONSTELLATION” i.e., the Business Organization. This sector focuses on making the product reach to the customer efficaciously. Having this sector bridges the gap between the suppliers/producers to the customers and this is one of the business areas where globalization means a lot in terms of spreading wings to other countries and to provide better quality service.

This era of advancement has made everything more dependent on technology like AI, robotics, big data, IOT etc. making the things easier at the same time posing some challenges to think about like reliance over human workforce etc. Hence, making a balance with the implementation of technology and use of human workforce is quite challenging.

This detailed transcript explains the wider effective areas within logistics by analyzing the Mahindra Logistics and also reflects on the growing demand for Industry 4.0 and its underlying outcomes for the business with special focus on positives of Information Technology. Finally, some recommendations have been suggested to pave their way towards successful implementation of advanced technologies to become self-reliant and reduces errors within the operations.

On concluding, the future of these logistics companies is tilted towards how much IT they can use in order to make themselves sustainable and to make the customers prove that the services are also being changes and adapted according to the time.

Part 2: Concept of Logistics and the risks underlying in a logistics system

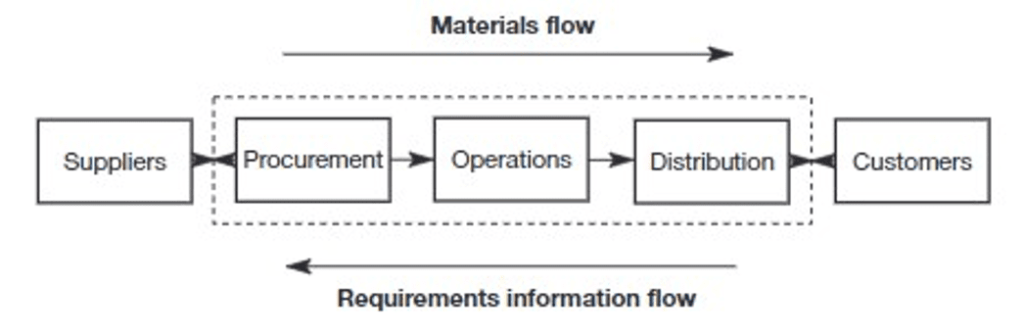

According to the Association for Operations Management, Logistics can be depicted as the art and science of obtaining, producing and distribution of materials and products to the required place and in the required quantities. (Jacobs & Chase, 2011).

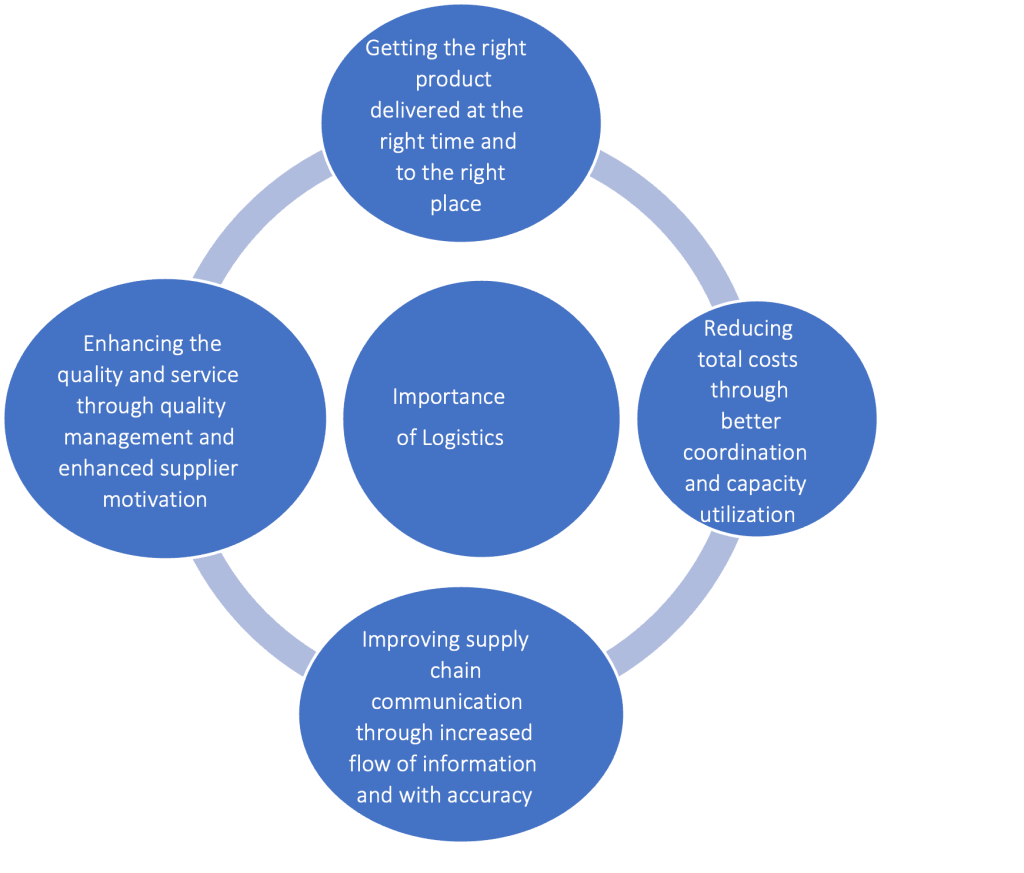

The following table explains the importance of logistics in the current times:

Logistics Operations is the taking care of the logistics activities of an organization i.e. managing of the material goods to the manufacturing unit and delivering these products to the end customers. These activities include sourcing, order processing, distribution planning, inventory and warehouse management, transportation etc. (Akinsolu, 2019).

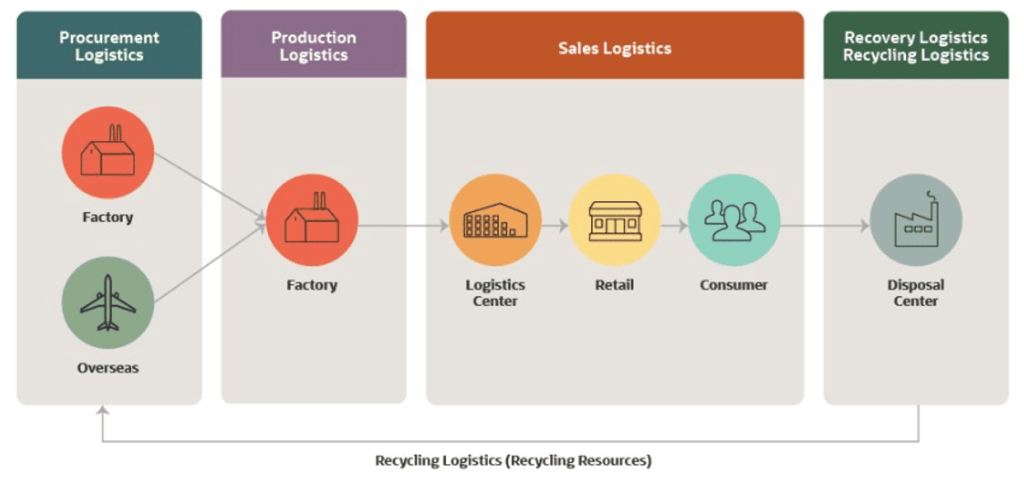

The following figure shows a detailed picture of logistics operations from the starting point to the destination and also the reverse logistics.

Executive Summary of Mahindra Logistics:

Mahindra Logistics Limited (MLL) is one of the renowned logistics and mobility services provider with hands-on experience and a perfect grip and presence in Indian Territory. They provide logistics services to various business sectors like automotive, engineering, fast-moving consumer goods (FMCG), pharmaceuticals etc. The special thing of this company is that they have integrated the technology in almost every aspect of their logistics service delivery. For example, warehouse management system for better warehouse management etc. And these aspects have been recognized by awarding them with the “CII Supply Chain & Logistics Excellence (SCALE)” for providing the best 3PL services in the years 2017,2018,2019,2020 (Warehousing – Mahindra Logistics L., 2020).

Logistics Operations in Mahindra Logistics

1. Warehousing

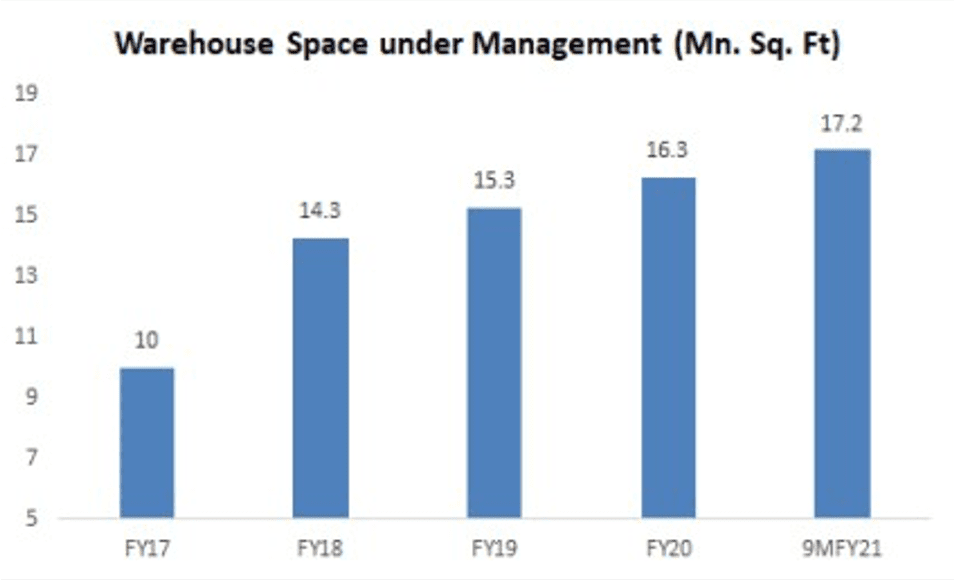

Warehousing in Mahindra Logistics is carried out in two different ways: one as a service to the customers and secondly as a part of integrated logistics solutions. The main activities in the warehousing sector include the inventory control, storage management and value-added services. The presence of warehouses is all-over India having a mix of built-to-suit [warehouse space is customized according to the requirements (Chadha, 2019)], dedicated, and multi-user warehouses (Warehousing – Mahindra Logistics L., 2020). The below figure shows the increase in the warehouse space of Mahindra logistics from financial year 2017 to 2021.

When it comes to the handling of the items and goods in the warehouse, a very well established and specialized Material Handling Equipment (MHE) and also extensive automation is being used and this has made the warehouse proficient enough to handle the existing warehouses in an optimized manner (Warehousing – Mahindra Logistics L., 2020). For example, Mahindra

Stiller is a Material Handling Equipment used in the daily warehouse management and operations which is of a great advantage in the shop floor including maintenance and offers trailers, trolleys, tipping trucks etc. (Engineering Review, 2015).

Warehousing activities are very much closely integrated with technology which helps them to provide much more customized services like sourcing, procurement, order management, inventory control, audit support which increased in the service delivery to the clients/businesses. In the recent years, Mahindra Logistics has planned to decrease its supplier base by 10% every year starting from 2014 in order to streamline its suppliers and reduce miscommunication problems between them. As a result of this, the suppliers will be decreased from 650 to 450 and has centralized the purchasing of the parts for two-wheelers and commercial vehicles. And this sourcing strategy will help the company to reduce atleast 2-3% of its purchasing costs from the supplier (Hogg, 2014).

2. Inbound Logistics

Inbound Logistics is the most customized logistics service provided to the customers where they create a logistics environment based on the requirement of the customer (Mahindra Logistics Ltd., 2020). This stage is a kind of an umbrella to carry out some important inbound logistical operations which are Stock receipts, stacking and tracking, to re-order quantities, inventory-aging process and high-value inventory maintenance, production plans (pull-out, sequencing, kit loading, trolley loading, double binning and trolley line up), replenishment plans to refuel the stock in the warehouse, return tracking, High value tracking (kit tacking and bin tracking) and minimizing the line processes (MahindraLogistics, 2017).

There are some important processes which are carried out in these operations like Stores and Line Feeding (SLF) process which include the kit creation and building, trolley loading and management of manufacturing parts that are of high-value, verification of materials (physically and receipt). And operations like Just-in-time (JIT) and Just-in-sequence (JIS) are also embarked in this stage (Mahindra Logistics Ltd., 2020)

3. Procurement, Packaging and Storage

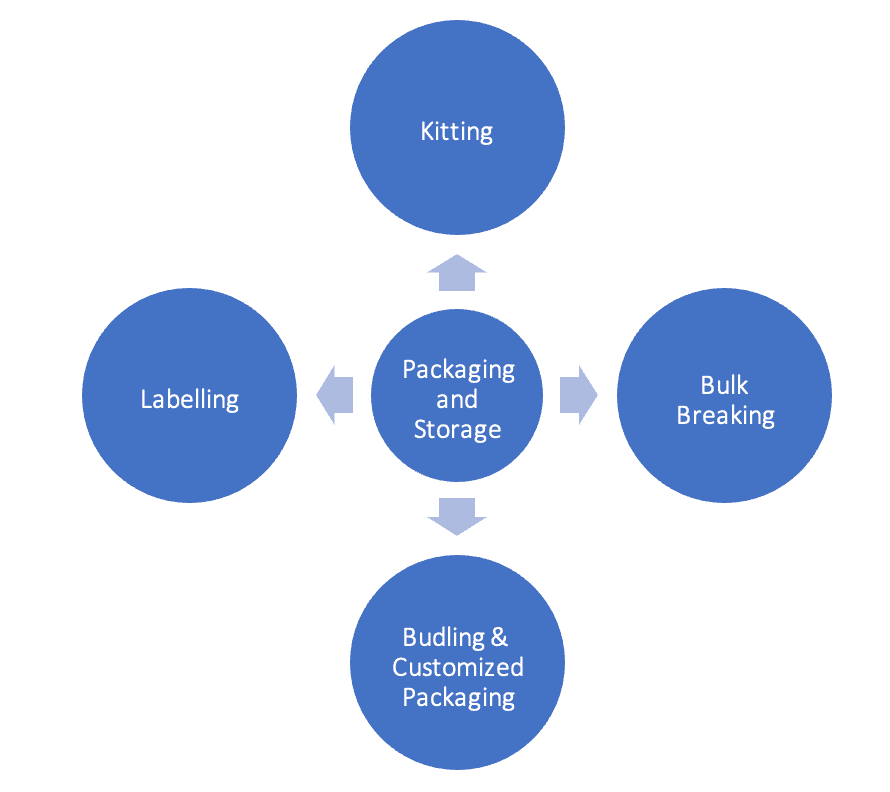

This section of Logistical Operations w.r.t Mahindra Logistics deals with packaging and some parts of inventory control and warehousing activities and mainly consists of packaging, labelling of different types of inventories and also providing customized packaging solution to the customers/clients. The below shows the main services provided by the Mahindra Logistics in this logistics sector.

Kitting can be defined as the inventory management technique where individual items (related to each other) are packaged together and shipped together as a single package (Weatherwax, 2022). In this process, one has to understand and determine what items will go into the kit and then the package is assigned with a new SKU number (Stock Keeping Unit Number) into the system. Then, assembling and arranging the items as a kit in a box and then shipping the kit/s to the consumer (Weatherwax, 2022).

Mostly, this service is used by Auto OEM’s (Original Equipment Manufacturer) and for consumer product companies when a consumer orders more than one item which helps in reducing shipping costs and the lead time for the delivery of the product to the consumers (MLL, 2019). Bulk Breaking is another value service provided which means to reduce a larger package into smaller package. Here, the larger package is received by the warehouse (nearest) and then according to the customer orders, this large package is then segregated into smaller ones (MLL, 2019). Moreover, than this, labelling activities are also carried in this section, where the use of technology is more i.e. use of RFID tags which is availed by all the customers. This step is completed in parallel to the kitting and bulk break activity, if the product has to travel more to the destination (MLL, 2019). Bundling is the opposite service of Bulk Breaking. Finally, comes the customized packaging services which is only made available when one of the above underlined services are used. This is a used in order to accommodate various parcel of different sizes, then in this case special packaging is made available in order to keep the product intact and its originality is not depreciated (MLL, 2019).

4. Vendor Managed Inventory (VMI)

Vendor Managed Inventory (VMI) is where the manufacturer or the supplier assumes the responsibility of inventory planning for the customer (SCRE SME, 2003). The main goal of this VMI Technique is to increase the collaboration between upstream department and downstream department in a supply chain (SCRE SME, 2003).

Recently, Mahindra Logistics have opened a distribution center/warehouse for the pharmaceutical industry which is a temperature-controlled warehouse for the medicines. With the creation of this, Mahindra Logistics have decided to manage the warehousing and distribution activities for its clients and this is an addition to the facilities provided to the clients apart from only inbound and outbound multi-modal transportation. This warehouse almost has all the required facilities like Material Handling equipment’s of all kinds, temperature control devices and techniques, customized storage space etc. (FRPT Research , 2020).

5. Transportation & Freight Forwarding

Mahindra Logistics has a capability of deploying a full stack of 10000 vehicles every month in order to provide the best and timely transportation facilities. They have a wider fleet of transport mode vehicles to facilitate its supply chain services to its customers (L, 2020). Apart from the transportation facilities, they also provide back-end transportation IT service and front-end devices in order to gather information and transmit real-time shipment data (L, 2020). They have a variety of transport facilities like inbound & outbound solutions, primary and secondary distribution, network-based distribution and last-mile delivery (L, 2020).

They also have subsidiary logistics partners like Lords Freight (India) Pvt. Ltd. (LORDS) because LORDS have an expertise in air and sea transport modes which helps in export and import services. With the help of this partnership, Mahindra Logistics is also providing International Freight forwarding services through air and sea modes like export and import operations, full container load, less than container load services and also integrated crossborder solutions for both domestic and international operations (Freight Forwarding-Mahindra Logistics, 2020).

The logistics system in Mahindra is developed in such manner which helps to provide some value-added services like route planning and network optimization which is safe, secure and timely delivery of the product, odd-dimension cargo (tailoring the transportation service to handle oversized cargo in a safe and secure manner) (MLL, 2019), last mile delivery is customized according to the customer requirements i.e., local distributor model, service provider model and unique distribution model etc. (MLL, 2019).

Reverse logistics by providing assistance in easy returns of the commodity goods back to the distributors, existence of cross-docking system (unloading the materials from the upstream directly to the customers) through consolidation and distribution for express delivery (MLL, 2019) and the last important service is the finished goods yards management which involves end-to-end management of all upstream to downstream activities including inspection, storage, maintenance, value-added services, quality control etc. (MLL, 2019).

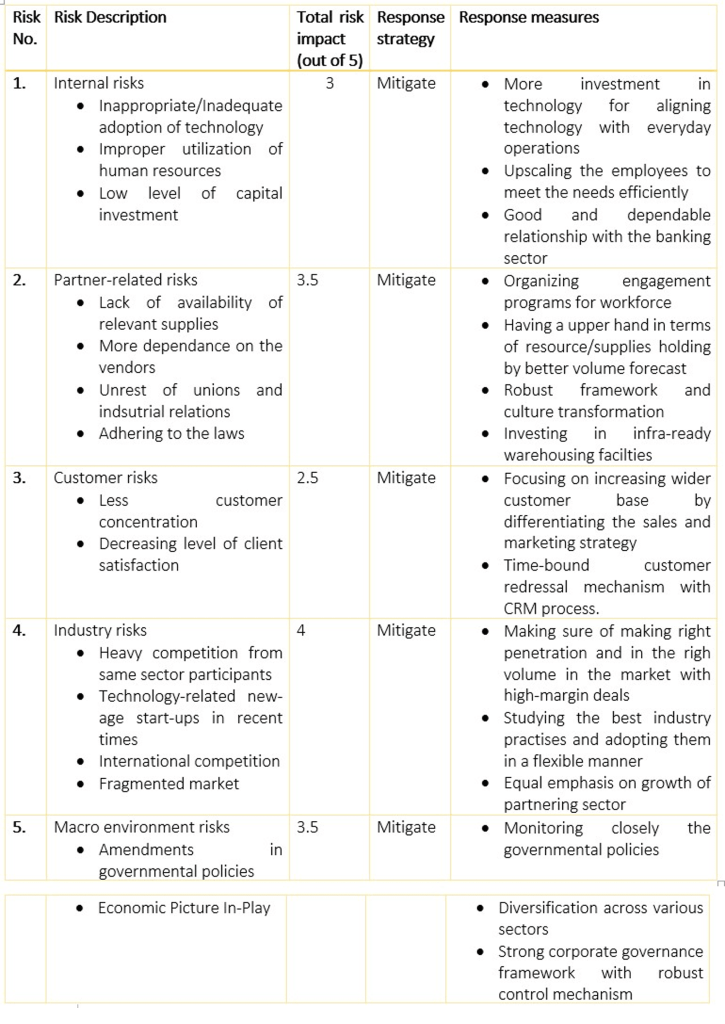

Risk Management in Mahindra Logistics

Risk Management can be defined as the process by which individual risk events and overall risk factors are identified and acknowledged accordingly in order to optimize success by reducing risks factors and increasing opportunities (Association of Project Management , 2021).

The following is the risks assessment and management table outlined for Mahindra Logistics (Annual Report Mahindra Limited, 2020).

Part 3: Information Technology and its role in shaping the logistics

Information Technology can be defined as the usage of technology in order to solve organizational and business-related problems using the means of software, computer systems and network infrastructure (Indeed Editorial Team, 2021).

In the current times, there has been an increase in the usage and adoption of IT systems and devices in the logistics operations. Some major contributions of information technology in logistics are as follows:

- Reducing the costs incurred in everyday operations by reducing less human workforce deployment and manual paperwork’s

- By eliminating the errors (human errors) and enhancing the quality of the tasks/operations

- Enabling the transfer and sharing the data between different players in the operations (Jadhav, 2015)

Use of Information Technology in Mahindra Logistics

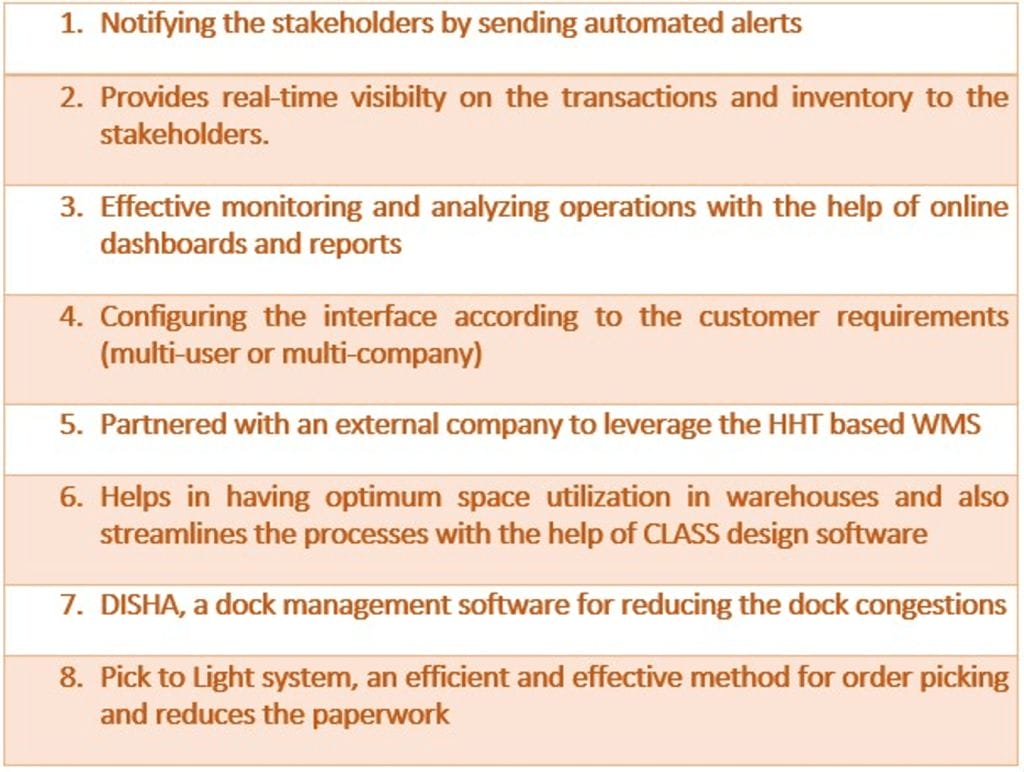

The following highlights the use of technology in Mahindra Logistics (Technology – Mahindra Logistics, 2020).

Warehouse Management System (WMS)

The WMS is mainly used in warehouse area in the logistics. The main objective of this WMS is to automate the warehouse operations and activities across all the established warehouses. With the help of WMS, the traditional warehouses have been modified by enhancing the efficiency and productivity of the activities happening in the warehouse. WMS has automated the process receiving, put away, picking and packing, kitting and shipping of the process. And helps in facilitating the inventory cycle count planning and execution (Technology – Mahindra Logistics, 2020).

The other benefits are that it also provides with the level of control which enables to better planning and management of resources and storage space. Also provides visibility of real-time inventory and order status (Technology – Mahindra Logistics, 2020).

The following table provides the info of other benefits gained by MLL

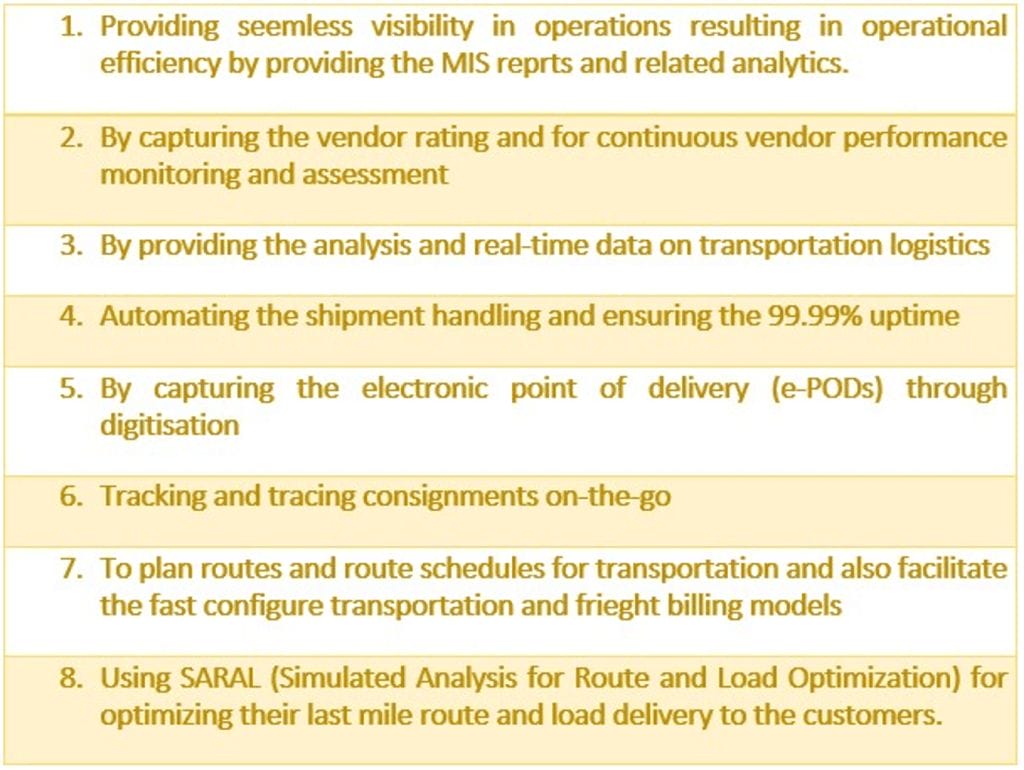

Transport Management System (TMS)

This TMS platform enables the MLL in having a collaborative logistics management network because it provides collaboration with customers, business associates and partners (Technology – Mahindra Logistics, 2020). It has saved many of the operations and freight costs with the help of shipment consolidation. This management system provides with 360◦ transparency in data sharing with all the stakeholders.

The major benefits gained by this system as are as follows

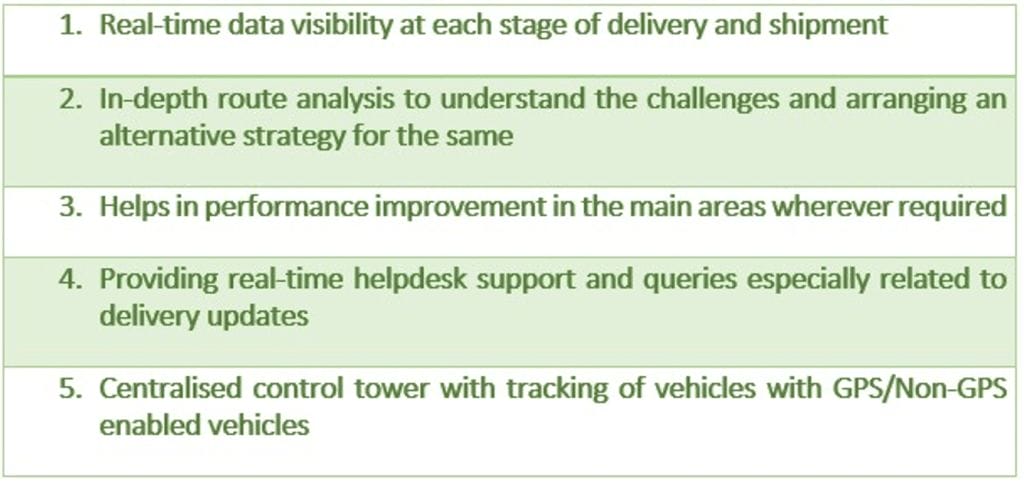

Telematics and Control Tower Operation (CTO)

Both Telematics and Control Tower mutually collaborate together to produce greater results in terms of providing end-to-end visibility to the whole logistics process. The CTO is the core for the logistics as it is the mode of communication related to the movement of goods and products. So, its like an eagle’s eye on the vehicles to ensure smooth deliver and timely one for the consumers (Technology – Mahindra Logistics, 2020).

The major use and advantage of the telematics and CTO are as presented:

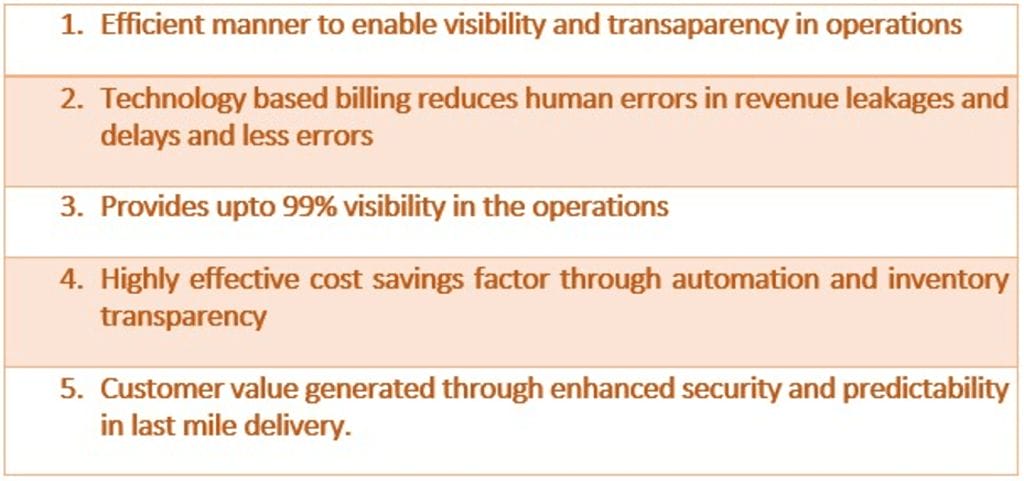

ALYTE Management System

As Mahindra Logistics uses EV’s in selected cities in India for their last mile delivery. This management system is a dedicated single platform to track all the EV vehicles, to mark the trip details and the kilometers for billing.

All the main components can be monitored using this system like tracking the vehicle. Monitoring the health of the EV etc. This is a single mobile app to track charge, manage the AC controls in the EV and also to lock and unlock the doors in the EV as well (Technology – Mahindra Logistics, 2020).

The main advantage are as listed below:

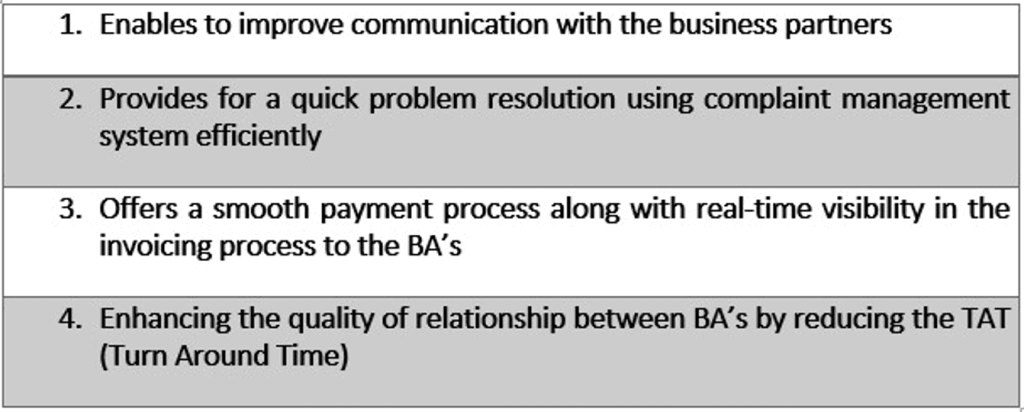

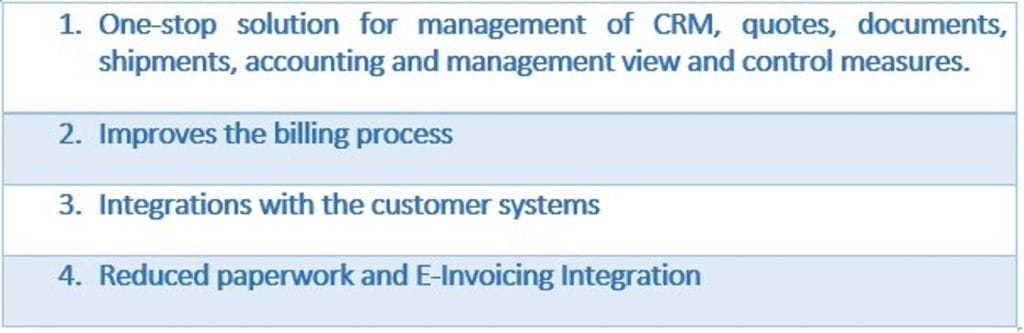

One-Touch Portal for BA Connect

This is a mobile/web-based application specially designed for the Business Associates (BA) connected with Mahindra to have a better engagement and transparency and to provide realtime updates regarding the activities (Technology – Mahindra Logistics, 2020). With this IT application, the following benefits have been achieved:

NextGen Solution for frieght forwarding

This system is used for daily communications with the customers, partners, agents and carriers.

The benefits of this system solution are highlighted below:

Part 4: Recommendations

Implementation of the following recommendation can assist Mahindra Logistics with increased efficiency in their current operations and will make the logistics business more sustainable and in-line with the current technologies in terms of collaboration, visibility and end-to-end communication.

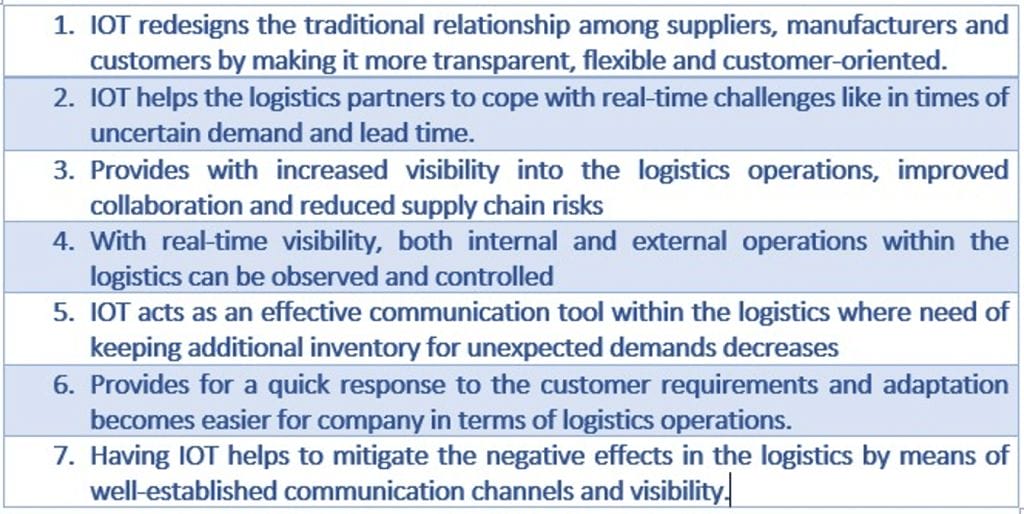

Implementation of Internet of Things (IOT)

With the evolution of Industry 4.0, it has enabled self-organized supply chains by means of implementing IOT. Hence, making this into a Smart SCM or SCM 4.0. In this current world, IOT is a necessary part of a business to collect and manage a lot of information transmitted from smart devices. The rationale behind suggesting this are as follows:

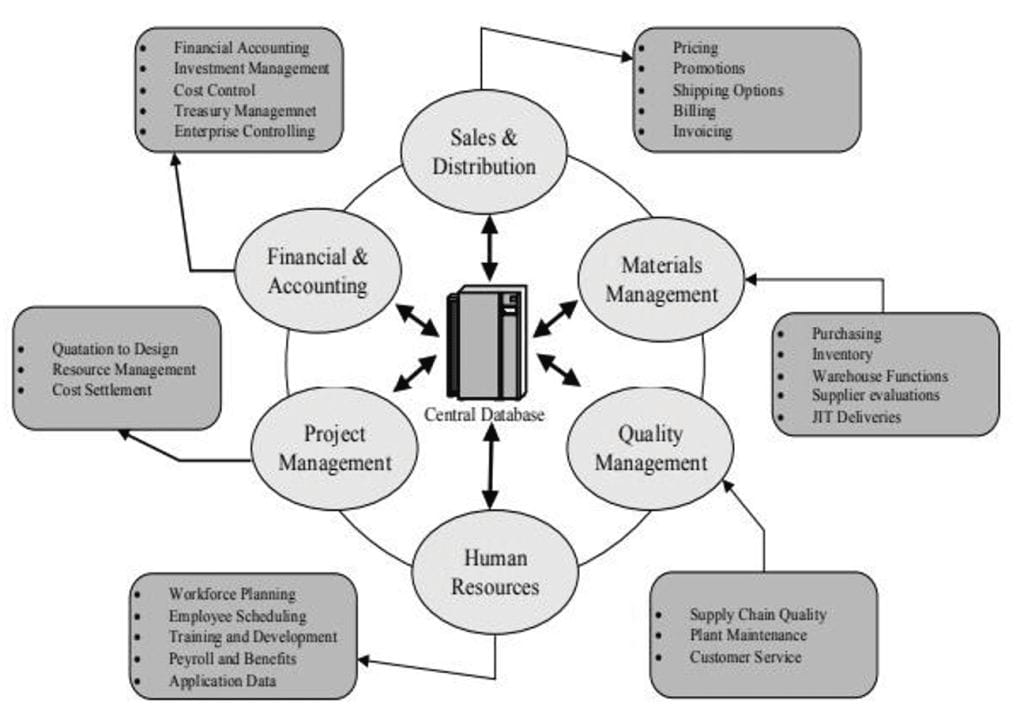

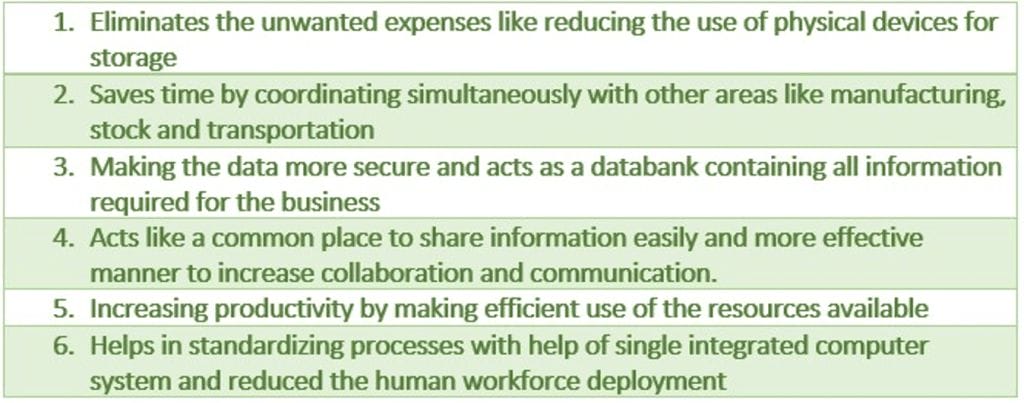

Use of Cloud Enterprise Resource Planning (CERP) System

ERP is an IT system which is a single-stop solution for all important and basic activities by making use of a single database for a business. Cloud ERP performs the same functions as of an normal ERP system but makes use of Internet or virtual servers instead of physical devices. The underlying benefits are mentioned below.

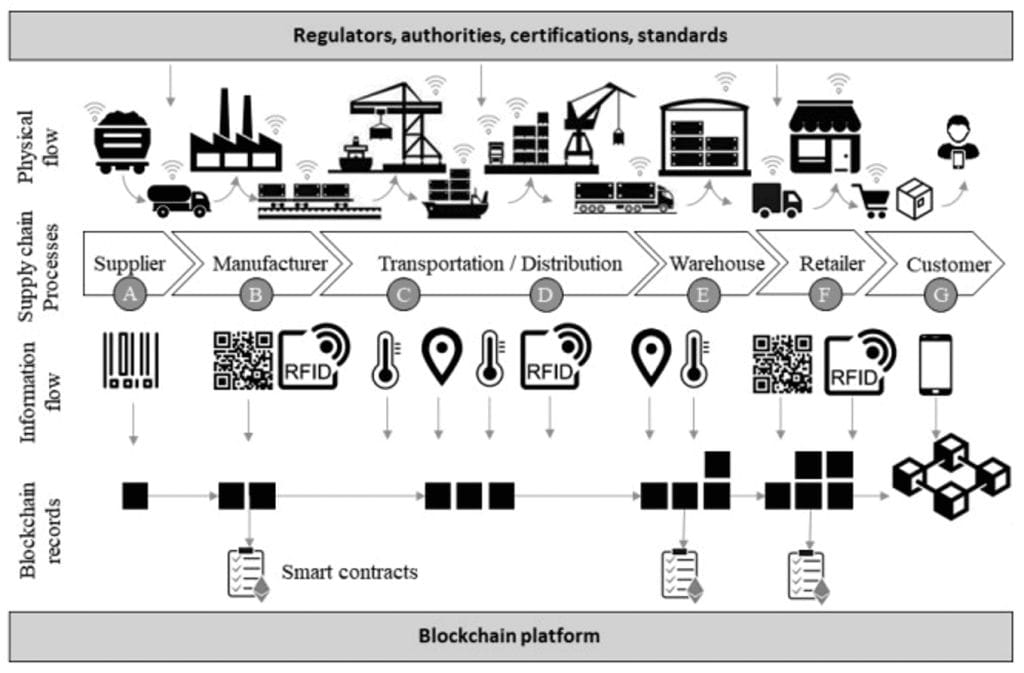

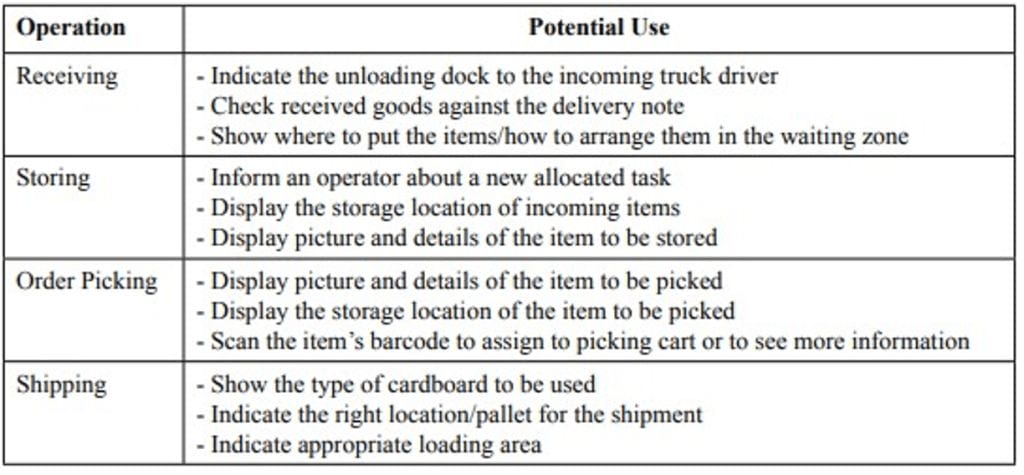

Make use of BlockChain Technology

Blockchain Technology has the capability to record each single transaction from the upstream till the downstream within as a series of blocks organized in a chronological order and linked with cryptographic proof (Paksoy, Kochan, & Ali, 2020). Blockchain Technology provides with unprecedented visibility and accountability with peer-to-peer, distributed and timestamping transactions in the logistics.

The hidden advantages for a business with adoption of it are as follows:

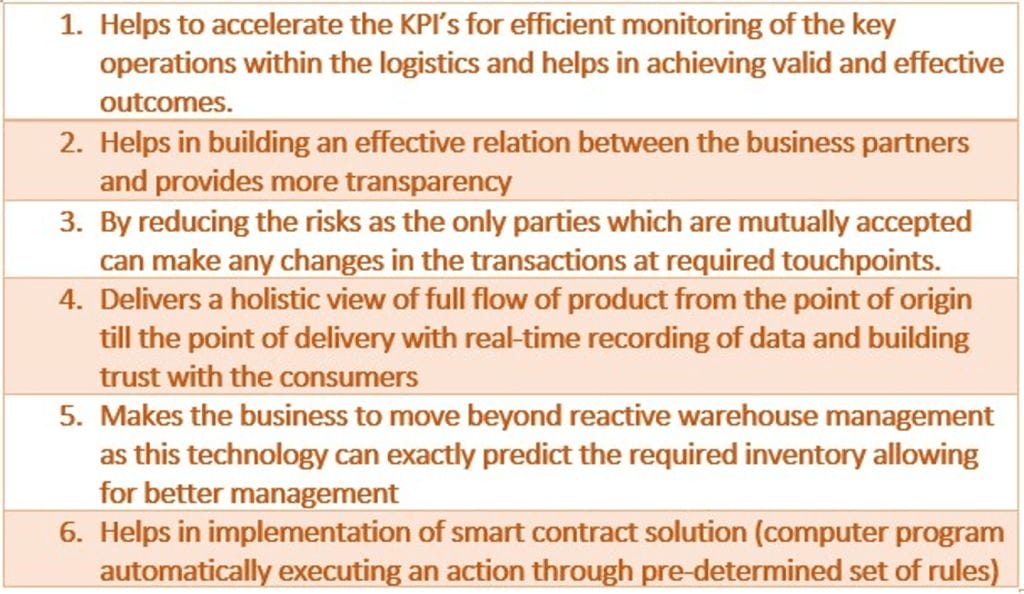

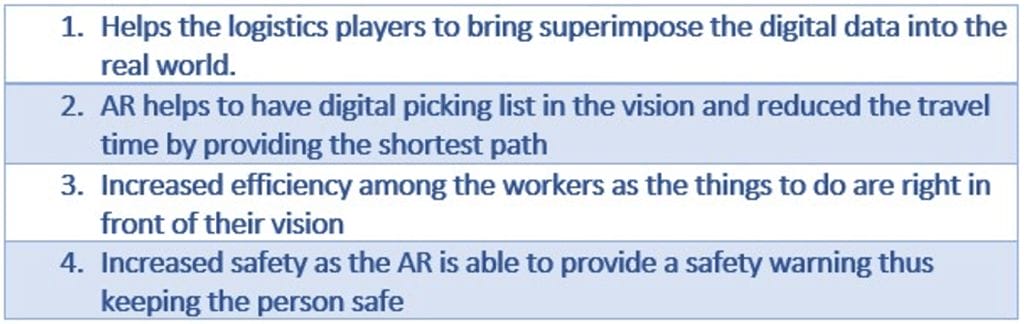

Use of Augmented Reality (ARs)

ARs are being currently used in many logistics areas like pick and services, collaborative logistics, procurement and last-mile delivery. And is a part of Industry 4.0. These systems just combine the real and virtual things in no-time and make us look them from a real-environment.

The benefits of ARs in logistics are highlighted below:

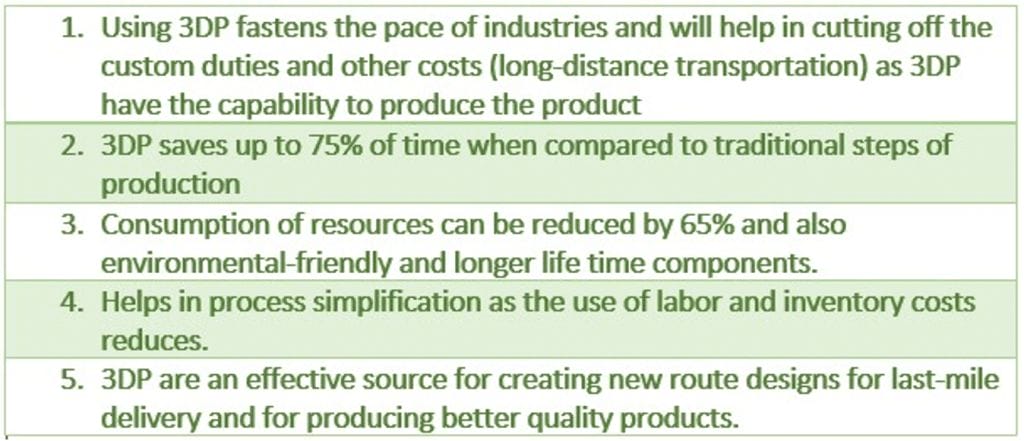

Implementation of 3D Printers (3DP)

In order to provide efficient delivery services to customers, pinpointing the correct delivery point is very important and making routes is crucial. Hence, 3DP can optimize this area of logistics, which can make the business save a large amount of time and costs. The following are the positive implication upon the logistics business.

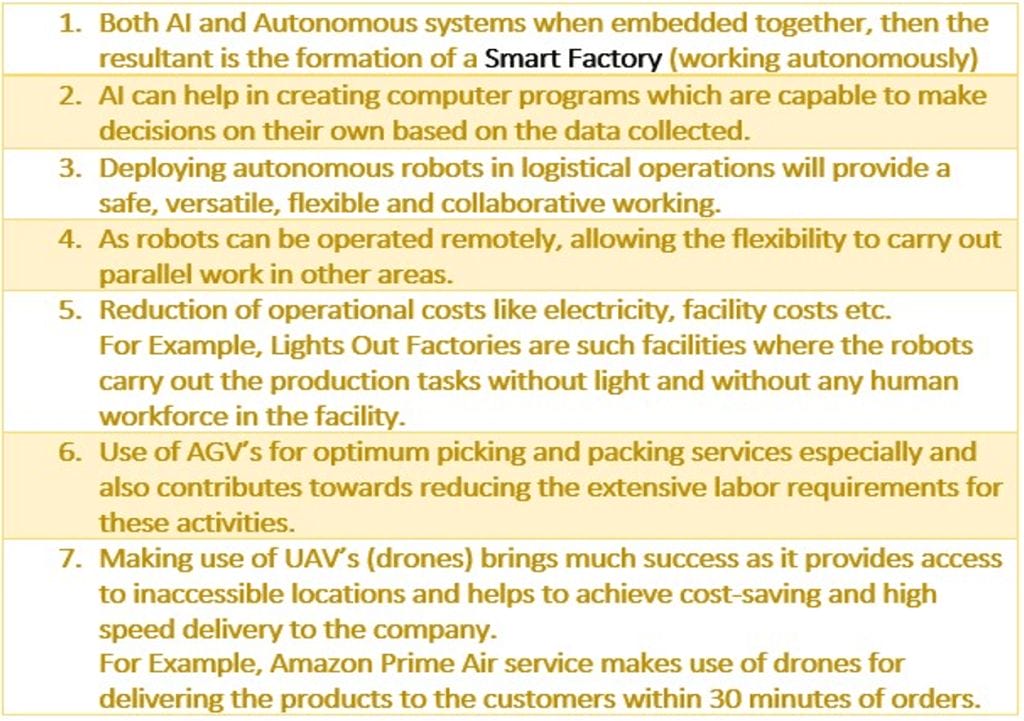

Use of Autonomous Systems, Artificial Intelligence and Robotics

The industry 4.0 is totally driven by the autonomous systems and artificial intelligence. When combined these two, provides the effective and productive results within the logistics effective areas. The resultant positives are listed below:

Part 5: Conclusion

The overall aim of all logistics companies is to make themselves sustainable by aligning to the current advancements and to keep the customers happy through best service delivery. In this ongoing Industry 4.0, these above factors can be achieved only through one dominant player i.e., IT which means a logistics company can make themselves the best compared to others through adoption of maximum IT services in their logistics operations. The reason behind this to make most of the services automated to the customers and to act on a real-time basis, to make the customers value the company. As we know that a coin cannot be stand straight, it will definitely tilt towards one way either heads or tails. Likewise, there are some initial challenges during implementation. But this Industry 4.0 tries to make this coin to stand straight i.e., making the logistics companies with help of IT gain as much competitive advantage they want and at the same time provide full satisfaction to the customers. The final words say that, the great player in the market will be determined through means of adoption of IT services appropriately.

References

Akinsolu, O. O. (2019, 04 22). Brief Overview of Logistics Operations. Retrieved from LinkedIn: https://www.linkedin.com/pulse/brief-overview-logistics-operationsolutola-o-akinsolu/

Annual Report Mahindra Limited. (2020). Earning Trust. Mumbai: Mahindra Logistics Limited.

Association of Project Management . (2021). What is risk management? Retrieved from Association of Project Management : https://www.apm.org.uk/resources/what-isproject-management/what-is-risk-management/

Chadha, S. (2019, 10 11). What is a Built-To-Suit Warehouse? Types and Benefits. Retrieved from Logisticsinsider.in: https://www.logisticsinsider.in/built-to-suit-warehousingthe-way-forward/

Chartered Institute of Procurement & Supply. (2012). The goals and contribution of strategic SCM . In T. C. Supply, Strategic Supply Chain Management (pp. 9-10). Lincolnshire: Profex Publishing Limited .

Christopher, M. (2011). The mission of logistics management. In M. Christopher, Logistics & Supply Chain Management (p. 11). Harlow: Pearson Education Limited.

Engineering Review. (2015, 10 27). Mahindra Stiller Materials Handling Equipment. Retrieved from Engineering Review: https://engmag.in/materials-handlingequipment-mahindrastiller/#:~:text=The Stiller battery operated hydraulic,%2C and tipping%20%26%20dumper%20trucks.

Freight Forwarding-Mahindra Logistics. (2020). Our belief in partnerships makes us leaders in Freight Forwarding. Retrieved from Mahindra Logistics: https://mahindralogistics.com/freight-forwarding/

FRPT Research . (2020). Mahindra Logistics opens state-of-art distribution centre in North India. FRPT – Infrastructure Snapshot, 7.

HDFC Securities. (2021). Initiating Coverage Mahindra Logistics Ltd. Mumbai: HDFC Securities Ltd.

Hogg, R. (2014). Mahindra to make supply chain more efficient. Retrieved from Automotive Logistics: https://www.automotivelogistics.media/mahindra-to-make-supply-chainmore-efficient/11563.article

Indeed Editorial Team. (2021, 11 30). What is information technology? (With skills and careers). Retrieved from Indeed Careers Guide: https://uk.indeed.com/careeradvice/finding-a-job/what-is-information-technology

Jacobs, F. R., & Chase, R. B. (2011). Logistics. In F. R. Jacobs, & R. B. Chase, Operations and Supply Chain Management (pp. 432-434). New York: McGraw-Hill/Irwin.

Jadhav, V. V. (2015). ROLE OF INFORMATION TECHNOLOGY IN SUPPLY CHAIN

MANAGEMENT. International Journal of Management Research & Review, 369-379.

Jenkins, A. (2020, 11 20). Logistics for Business Defined: Importance Role & Benefits.

Retrieved from Oracle NetSuite: https://www.netsuite.com/portal/resource/articles/erp/logistics.shtml#:~:text=Imp ortance%20of%20Logistics&text=In%20business%2C%20success%20in%20logistics,a nd%20an%20improved%20customer%20experience.

Kshetri, N. (2021). The roles of blockchain in achieving various strategic supply chain objectives. In N. Kshetri, BLOCKCHAIN AND SUPPLY CHAIN MANAGEMENT (pp. 4243). Oxford: Elsevier Inc.

L, M. (2020). A comprehensive transport service provider with solutions to fit your business.

Retrieved from Mahindra Logistics : https://mahindralogistics.com/transportation/

Lu, M. (2018, May 11). Five Ways Augmented Reality Enhances Supply Chain Management.

Retrieved from Association for Supply Chain Management: https://www.ascm.org/ascm-insights/five-ways-augmented-reality-enhances-supplychain-management/

Mahindra Logistics Ltd. (2020). Optimising in-factory logistic operations with the most holistic solutions. Retrieved from Mahindra Logistics: https://mahindralogistics.com/in-factory-logistics/

Mahindra Stiller Auto Trucks Limited . (2015). Retrieved from Stiller: http://www.mahindrastiller.com/

MahindraLogistics. (2017). IN-FACTORY LOGISTICS. Retrieved from Mahindra Logistics: https://www.hindustaninformatics.com/solutions/in-factory-logistics.html

Michigan State University . (2022, 01 18). Why Logistics is Fundamental to Supply Chain Success. Retrieved from Michigan State University: https://www.michiganstateuniversityonline.com/resources/supply-chain/logisticsfundamental-to-supply-chain-success/

MLL. (2019). MAHINDRA LOGISTICS LIMITED INVESTOR PRESENTATION Q2 FY20. Retrieved from Mahndra Logistics Ltd.: https://mahindralogistics.com/wpcontent/uploads/2019/12/Investor-Presentation-November-2019.pdf

Paksoy, T., Kochan, C. G., & Ali, S. S. (2020). Logistics 4.0: Digital Transformation of Supply Chain Management. Boca Raton: CRC Press.

SCRE SME. (2003). Supply Chain Resource Cooperative. Retrieved from NC State University:

https://scm.ncsu.edu/scm-articles/article/vendor-managed-inventory-vmi-threesteps-in-making-it-work

Sophir, E. L., Wang, E., & Wegrzyn, K. E. (2022, February 10). Blockchain for Digital Logistics and Smart Warehouses. Retrieved from The National Law Review: https://www.natlawreview.com/article/blockchain-digital-logistics-and-smartwarehouses

Technology – Mahindra Logistics. (2020). Leading the logistics industry with tech enabled services. Retrieved from Mahindra Logistics: https://mahindralogistics.com/technology/

Warehousing – Mahindra Logistics L. (2020). Optimising in-factory logistic operations with the most holistic solutions. Retrieved from Mahindra Logistics: https://mahindralogistics.com/warehousing/

Weatherwax, J. (2022). Kitting Meaning: What is Kitting? Retrieved from BlueCart: https://www.bluecart.com/blog/kitting-meaning